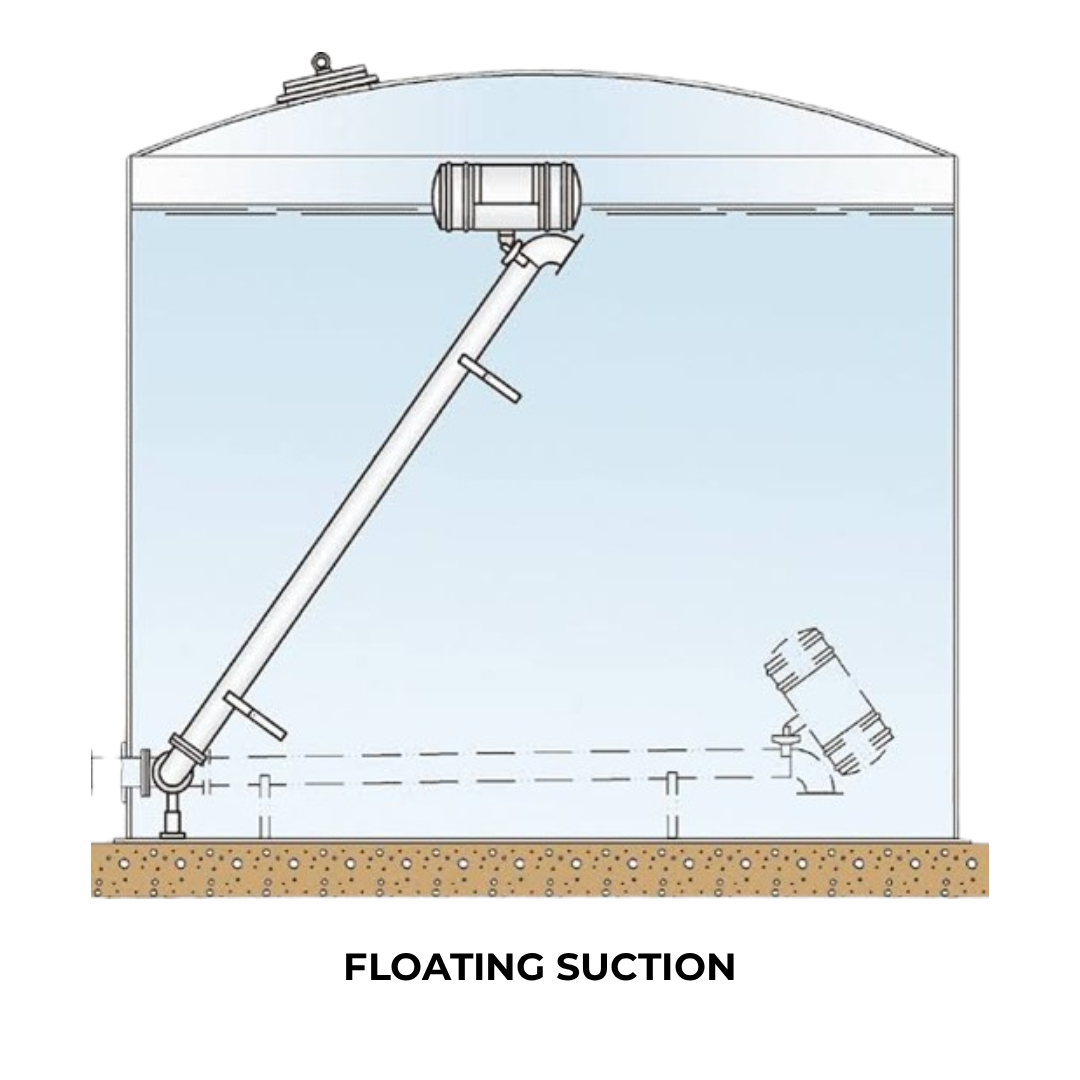

In a storage terminal handling white petroleum products, floating suction units are used to ensure that only clean, uncontaminated fuel is drawn from the tanks, preserving product quality and safety, reducing the risk of contamination. This is especially important in ensuring high-quality fuels for our end users, including vehicles and aircraft, where product integrity is key.

Vermont engineered Floating Suction is designed to streamline storage terminal workflows. By automatically adjusting to fluctuating liquid levels, it ensures a consistent, uninterrupted flow of your valuable white petroleum products. This unit’s innovative design maximizes operational efficiency, while prioritizing the safety of your team.

Key Features:

- Minimizing Contamination: Our floating suction unit helps by drawing the product from near the surface, where it’s generally cleaner, and prevents the suction of unwanted contaminants from the tank bottom.

Maintaining Product Integrity: White petroleum products require high purity for proper storage and transport. Floating suction units are critical to ensure that only the cleanest, highest-quality liquid is being pumped out, preventing the introduction of water, particulate matter, or sludge, which can degrade the product. This is especially crucial in the transportation of refined fuels where even small amounts of contamination could cause problems like engine knocking, corrosion, or operational failures in end-use equipment.

Vermont Technologies Pvt. Ltd.

Facility

Plot No. PAP-A-8/6, “A” Block, Phase IV

MIDC Chakan, Opp Mahindra Vehicle

Dist. Pune 410501

Maharashtra, India

Tel: (+91) 9168176683 / 9168179461

E-mail: ho@vermonttechnologies.co.in

Why choose Vermont?

The Leader in Positive Displacement Flow Metering

A total solutions technology company

Customised Solutions

Easy Accessibility

Excellent After-sales Service

A customer-centric work culture